It's been some time since I've posted anything, but I should be updating this more frequently now. I've since moved into a MUCH larger workshop and still have a massive amount of work to complete before I'm ready for any more machine tool mods or upgrades, but I had been slowly working on a few of my projects at the old house. Here's a few pics for now, more to come later...

One Overachievier's Perspective...

A temporary documentary to cover the trials, errors, and successes as I modify nearly all the machine tools I own to better fit my projects, my style of work, and my lifestyle. I may vent here at times due to the assholes and idiots I deal with on a daily basis, but the biggest part of any post should cover machine tool mods and their details.

Saturday, April 2, 2011

Thursday, November 18, 2010

Tooling Plate & Spacer Blocks Update

Almost forgot-here's some pics I should have shown sooner of the blocks I had made to raise my tooling plate above the surface of my Taig's table (the last thing I'd been rambling on about before the "sins and temptations of the flesh" thing that's kept me so busy after school and work lately). The tooling plate has been mocked up for initial measurements and data although not much else has been done with it as of yet. My schedule should open up a bit more in early December so there should also be more time for my projects with working forty or fifty hour weeks and a month break from classes...

All five of the blocks have since been finished and ground together: one 0.484x1x4" for the center of the plate and four 0.484x2x4" to be spaced equally along the length of the table. More holes will still have to be drilled and counterbored or tapped in order to use all five blocks, but I believe the additional support under the tooling plate with them will prove to deflect under loads much less then using only three of this size (as I have mocked up under the tooling plate at this time). I would guess that the installation of these blocks will also help to strengthen the Taig's aluminum table a small amount-a few other factors come into play here and since I'm no engineer I can't really say for certain, but it seems like adding a few braces and a backing plate as thick as or thicker than the thinnest portion of an extruded flat plate would in most cases add a bit of structural support to the original extruded flat plate alone.

These pics were posted in my last post also, but there are also some pics of a stepper motor threaded mount cover I had built for the Taig with an engraved reference line for the micrometer dials after the first four...

All five of the blocks have since been finished and ground together: one 0.484x1x4" for the center of the plate and four 0.484x2x4" to be spaced equally along the length of the table. More holes will still have to be drilled and counterbored or tapped in order to use all five blocks, but I believe the additional support under the tooling plate with them will prove to deflect under loads much less then using only three of this size (as I have mocked up under the tooling plate at this time). I would guess that the installation of these blocks will also help to strengthen the Taig's aluminum table a small amount-a few other factors come into play here and since I'm no engineer I can't really say for certain, but it seems like adding a few braces and a backing plate as thick as or thicker than the thinnest portion of an extruded flat plate would in most cases add a bit of structural support to the original extruded flat plate alone.

These pics were posted in my last post also, but there are also some pics of a stepper motor threaded mount cover I had built for the Taig with an engraved reference line for the micrometer dials after the first four...

Tuesday, October 5, 2010

New Workshop Arrangement

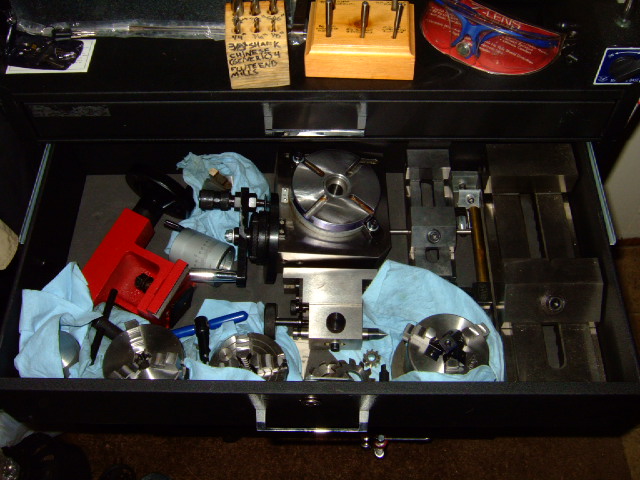

Different people cope with death in different ways-I just have to stay busy until it doesn't bother me anymore and I'm usually okay. There's been more than enough work to keep me busy with the family lately, but I've also busted my rump organizing my work area to help keep my mind off things. Since it's been both cold and rainy here over the last few days, I wasn't able to use the door to the outside to temporarily move, sit, or store items being shuffled or in transit so that resulted in more clutter through the adjoining rooms. It's a huge relief to have all my tools here organized (I still have two Craftsman tool chests full of hand tools, MIG and arc-welding equipment, a large oxy-acetylene outfit, a 30 gallon 6HP Craftsman air compressor, and many more related tools-nearly enough for a shop!), I just need to move to a larger place in order to have all my tools available to me.

Here's some pics-don't worry about the chest, I'm going to pick up some large, thin plastic sheet and aluminum angle asap to build an enclosure for the Taig. I can't have it that close to my tool box without some sort of one...

Here's some pics-don't worry about the chest, I'm going to pick up some large, thin plastic sheet and aluminum angle asap to build an enclosure for the Taig. I can't have it that close to my tool box without some sort of one...

That's been a load of work, but it needed to be done. I feel bad because I've gotten so far behind on nearly everything else, but I'll do my best to get caught up as soon as I can. More to come soon...

Subscribe to:

Comments (Atom)